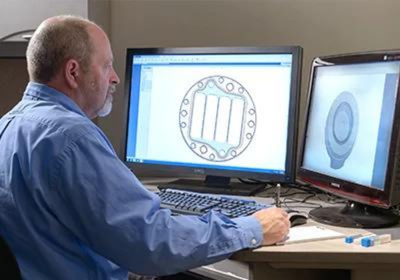

In-House Tooling: The Cornerstone of Plastic Injection Molding Excellence

Where precision meets performance, efficiency and durability

In today's competitive manufacturing landscape, every second and dollar counts. That's why TechNH brings you the game-changing advantage of in-house tooling capabilities – your key to faster, more precise and more cost-effective plastic injection molding.

- Up to 40% faster project turnaround times

- Significant cost savings on mold maintenance

- Superior quality control with instant adjustments when needed

- Greater flexibility for design modifications and customization

Whether you're launching a new product or optimizing existing ones, our advanced electrical discharge machining (EDM) technology and experienced tooling specialists ensure your success from day one.

Ready to experience the difference in-house tooling can make for your manufacturing project? Download “The Tooling Edge: Why In-House Capabilities Are a Game-Changer for Manufacturers” to learn more about the strategic advantages of in-house tooling.

Download the Tooling Edge White Paper

Why Custom Plastic Injection Molding with TechNH

Our in-house team of plastics engineers has decades of industry experience in polymer science, material selection, processing techniques and product design. Whether you’re developing an updated version of an existing component or designing something new, our team takes a hands-on, consultative approach with our customers. We provide any necessary support throughout the process, to make improvements over multiple iterations, from your first pass to a final product that’s ready for manufacturing.

Comprehensive Molding Options

Experience the freedom of extensive molding options with TechNH. Our advanced molding capabilities allow for a wide range of shapes, sizes and configurations to bring your vision to life.

Complex Designs Welcomed

At TechNH, we thrive on complexity. We welcome the challenge of intricate designs and complex geometries, turning your most ambitious ideas into reality.

Quality Assurance

Above all else, quality is our top priority. We adhere to rigorous quality assurance standards throughout each step of the molding process to ensure that our products meet the highest industry standards and compliance.

Advanced Technology

TechNH leverages cutting-edge technology and state-of-the-art equipment to deliver high-quality plastic injection molding solutions that meet the most demanding industry standards.

Dedicated Support Team

TechNH provides dedicated support throughout the entire plastic injection molding process, from initial design consultations to post-production assistance, ensuring a smooth and hassle-free experience.

Fast Turnaround Times

TechNH prioritizes efficient production timelines, ensuring that your projects are completed promptly and delivered on schedule. FY 2023 - 99.7% on-time delivery.

Seamlessly transfer your tool to eliminate problems and protect your business

Precision Injection Molding Capabilities from TechNH

Plastic Injection Molding

We offer a wide range of molding capabilities, including insert molding and over-molding, ensuring that we can tackle even the most complex geometries with precision and efficiency.

Tooling

Our in-house capabilities enable us to craft some of the most complicated molds in the industry, all while maintaining the highest standards of quality and precision.

Engineering

Whether your ideas arrive on the back of a napkin or as a stack of intricately designed plans, we have the expertise and technical prowess to bring them to life.

Regulatory

TechNH staffs an in-house regulatory team for standards compliance on your critical applications.

Quality

We boast a state-of-the-art metrology lab staffed with trained quality engineers who meticulously scrutinize every aspect of production to guarantee adherence to the highest standards.

Cleanroom

Our facilities include a dedicated ISO Class 7 hard-walled cleanroom and three Class 7 soft-walled cleanrooms, providing cleanliness and precision throughout the manufacturing process.

Learn More about TechNH

Market Expertise

Medical

Our expertise spans a wide range of applications, including lab equipment, patient monitoring, diagnostic, orthopedic and surgical components and blood handling.

Defense

From ITAR compliance to specialized components, we ensure durability and reliability for defense contractors and military organizations.

Water Treatment

TechNH delivers high-quality injection molding components for water treatment equipment, ensuring efficiency and longevity in filtration systems, valves, chemical pumps and more.

Industrial

Whether you operate in construction, non-invasive medical, consumer goods, agriculture, industrial, recreation or hardware sectors, we address your mechanical, chemical, and operational challenges promptly and cost-effectively.

Alternative Energy

Our expertise lies in crafting precision-engineered internal frames that form the backbone of green hydrogen and carbon electrolyzer systems.

CUSTOMER VOICES

"What we have in our relationship is special. This is why we come back again and again to TechNH to help us with our molding needs. You guys are the best!”

– PA Customer

Registered

UL Recognized

13485:2016

Registered